Introduction

Nuts, bolts, and washers are essential parts that hold many machines and structures together. Making sure these parts fit well and it is very important for keeping things safe and working right. But sometimes, the importance of correctly matching these components according to their grade and specifications is often overlooked. This guide offers an in-depth examination of why matching is import, the potential risks of mismatches, and how to match nuts and washers with bolt grades.

How to Match Nuts and Washers with Bolt Grades?

The following are five different categories of bolts, and it is recommended to use nuts and washers that match the strength and application of the bolt. Here’s a quick guide:

-

Hex bolt, hex cap screw, carriage bolt, hex flange bolt, squre bolt, plow bolt, U bolts, splice bolt, T bolt, socket cap screw, timber bolt,etc.:

| Bolt grade | The grade of recomment nut | The grade of recommend washer |

|---|---|---|

| SAE J429 Gr.2 | SAE J995 Gr.2 | N/A |

| SAE J429 Gr.5 | SAE J995 Gr.5 | N/A |

| SAE J429 Gr.8 | SAE J995 Gr.8 | N/A |

| ASTM A307 Gr.A | ASTM A563 Gr.A | N/A |

| ASTM A307 Gr.B | ASTM A563 Gr.A | N/A |

-

Thread rods and headed bolt:

| Bolt grade | The grade of recomment nut | The grade of recommend washer |

|---|---|---|

| ASTM A193 B7 | ASTM A194 Gr.2H | F436 |

| ASTM A193 B8 class1 | A194 Gr. 8 | SS304 |

| ASTM A193 B8M class1 | A194 Gr. 8M | SS316 |

| ASTM A193 B8 class 2 | A194 Gr. 8 | SS304 |

| ASTM A193 B8M class 2 | A194 Gr. 8M | SS316 |

-

Steel transmission tower bolt:

| Bolt grade | The grade of recomment nut | The grade of recommend washer |

|---|---|---|

| ASTM A394 Type 0 | ASTM A563 Gr.A | F436 |

| ASTM A394 Type 1 | ASTM A563 Gr.DH | F436 |

| ASTM A394 Type 3 | ASTM A563 Gr.DH3 | F436 |

-

Anchor bolt:

| Bolt grade | The grade of recomment nut | The grade of recommend washer |

|---|---|---|

| ASTM F1554 Grade 36 | ASTM A563 Gr.A | F436 |

| ASTM F1554 Grade 55 | ASTM A563 Gr.A | F436 |

| ASTM F1554 Grade 105 | ASTM A563 Gr.DH | F436 |

-

Heavy hex structural bolts:

| Bolt grade | The grade of recomment nut | The grade of recommend washer |

|---|---|---|

| ASTM A325 | ASTM A563 Gr.DH | F436 |

| ASTM A490 | ASTM A563 Gr.DH | F436 |

The Advantages of Right Matching

- Preventing Failure: The right combination of bolt, nut, and washer ensures that the assembly can withstand the operational stresses it will face, reducing the risk of failure.

- Corrosion Resistance: Different materials and grades offer varying levels of corrosion resistance. Matching materials correctly can prevent galvanic corrosion and extend the lifespan of the assembly.

- Maintaining Tension: A correctly matched assembly will maintain the required tension and preload, ensuring the joint’s stability under load.

The Risks of False Matching

False matching may cause the following problems:

- Joint Failure: An improper match can result in inadequate preload, leading to loosening and eventual joint failure.

- Corrosion: Using incompatible materials can accelerate corrosion, compromising the structural integrity of the assembly.

- Increased Wear: Incorrectly matched components can increase friction and wear, leading to premature failure.

What to Consider When Choosing the Right Nuts and Washers:

- Bolt Grade: The strength of a bolt determines the grade of nuts and washers required to match its load-bearing capacity.

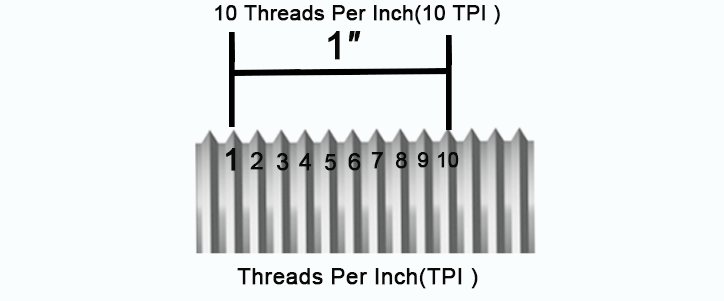

- Size: Make sure the nut and washer are sized appropriately for the bolt diameter and length to evenly distribute the load.

- Environmental conditions: Consider the environment in which the component will be used. For harsh conditions, materials with higher corrosion resistance should be selected.

- Application requirements: Consider the loads, vibrations and temperatures the component will be subjected to and select components that can withstand these conditions.